o 50% to 70% enhancement in power-rating over PIX-X'act® HTD/STD Belts

o Higher angular speed, resistance to loads and low noise

o Optimum operational efficiency and augmented Belt life

o Lower operational cost

o Anti-static properties as per ISO 9563

o Oil & heat resistance

o Temperature resistance up to 100°C

INTRODUCTION AT TIMING BELT aka TOOTHED BELTS,SYNCHRONOUS BELTS

Timing Belt

PIX is the leading manufacturer and exporters of Belts that are widely used in almost all industries. PIX Industrial Belts are available in Wrap Construction, Raw Edge Cogged, Poly-V and Timing Belt construction, besides there is also a wide range of special construction Industrial Belts which are also termed as application-specific Industrial Belts.

PIX also provide a complete solution along with Industrial Belts, with matching set of Pulleys, Bushes and couplings. PIX industrial Belts are widely used in textile industry

PIX Industrial Belts are known for their quality, reliability, and an extended service life.

PIX is the leading manufacturer of Industrial Timing Belts. PIX Synchronous Belts are designed and manufactured at its state-of-the-art facility. PIX offers a vast range of Industrial Synchronous Belts, they are available in MXL, XL, L, H, XH, XXH, S2M, S3M, S5M, S8M, S14M, 2M, 3M, 5M, 8M, 14M sections. Key features of Industrial Synchronous Belts

- High efficiency due to positive engagement between Belt teeth and pulley grooves.

- Fibreglass cord provides strength, excellent flex life & high resistance to elongation

- Exact power transmission.

- Low noise level & longer service life.

- Improved stress distribution.

- Temperature range: -25ºC to +100ºC

PIX Industrial Synchronous Belts are suitable for drives demanding exact power transmission .Typical for textile machinery, CNC machines

PIX-TorquePlus®-XT2 High-power Timing Belts

Features

Constructional Details

| Section | Pitch (mm) | Tooth Height (mm) | Belt Thickness (mm) | Manufacturing Range | Sleeve Width (mm) | Length Designation | |

|---|---|---|---|---|---|---|---|

| Min. (mm) | Max. (mm) | ||||||

| TP2-5M | 5.00 | 2.06 | 3.80 | 300 | 2250 | 465 | Lp |

| TP2-8M | 8.00 | 3.48 | 6.00 | 344 | 4464 | 460 | Lp |

| TP2-14M | 14.00 | 6.02 | 10.00 | 966 | 4578 | 420 | Lp |

| TP2-S5M | 5.00 | 1.91 | 3.40 | 350 | 2525 | 465 | Lp |

| TP2-S8M | 8.00 | 3.05 | 5.30 | 376 | 3200 | 460 | Lp |

- Specially designed flexible neoprene compound offers high resistance to fatigue and adverse environmental conditions

- Fibreglass cords for enhanced stability against dynamic load conditions, high resistance to elongation, offers excellent flex life and high tensile strength

- High modulus teeth rubber for superior power transmission and high resistance to oil and heat

- Specially woven fabric resistant to heat and abrasion protects the teeth from damage

Product Range

Reference standards

ISO 13050

Applications

Food processing machines, paper & packaging machines, printing machines, robotic equipment, conveyors, office equipment, medical equipment, dough mixers, textile machines, etc.

Product Label

PIX-X'act® STD Timing Belts

Features

o High efficiency due to positive engagement between Belt teeth and pulley grooves

o Fibre-glass cord provides strength, excellent flex life & high resistance to elongation

o Exact power transmission

o Low noise level & longer service life

o Improved stress distribution

Constructional Details

1. Polychloroprene backing

2. Fibre-glass cord for superior tensile strength & minimum elongation

3. High modulus Fibre loaded Polychloroprene rubber compound

4. Nylon stretchable fabric teeth for high wear resistance

| Section | Pitch (mm) | Tooth Height (mm) | Belt Thickness (mm) | Manufacturing Range | Length Designation | |

|---|---|---|---|---|---|---|

| Min. (mm) | Max. (mm) | |||||

| S-2M | 2.00 | 0.76 | 1.36 | 60 | 3700 | Lp |

| S-3M | 3.00 | 1.14 | 2.20 | 120 | 6510 | Lp |

| S-5M | 5.00 | 1.91 | 3.40 | 150 | 4000 | Lp |

| S-8M | 8.00 | 3.05 | 5.30 | 376 | 6640 | Lp |

| S-14M | 14.00 | 3.05 | 10.20 | 714 | 5012 | Lp |

Product Range

Reference standards

Conforms to ISO 13050, ISO 5294 & ISO 5296

Applications

Suitable for drives demanding exact power transmission such as robotic machines, textile machinery, CNC machines, electronic equipment such as printers,

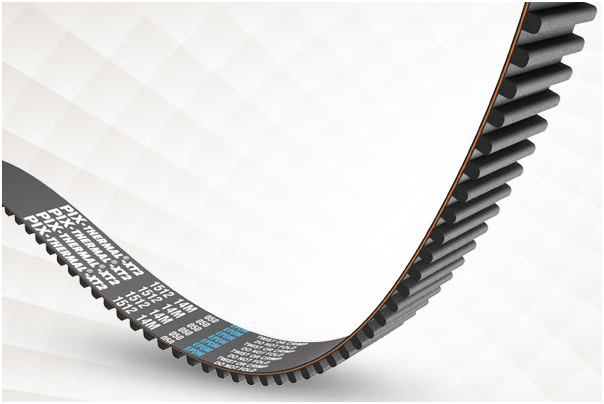

PIX-Thermal®-XT2 High-power, EPDM Timing Belts

Features

o Superior power transmission over PIX-TorquePlus®-XT2 Belts

o Higher angular speed, resistance to loads and low noise

o Optimum operational efficiency and augmented Belt life

o Lower operational cost

o Anti-static properties as per ISO 9563

o Ozone resistance

o Temperature range -35°C to 130°C

Constructional Details

1. The special compound, resistant to crack, offers superior flexibility

2. Specially treated glass cords for superior tensile strength and minimum elongation

3. High modulus fibre loaded EPDM rubber compound for superior teeth adhesion and enhanced power transmission

4. Nylon stretchable fabric teeth for high wear resistance

Product Range

Reference standards

ISO 13050

Applications

Food processing machines, paper & packaging machines, printing machines, robotic equipment, conveyors, office equipment, medical equipment, dough mixers,textile machines, etc.

| Section | Pitch (mm) | Tooth Height (mm) | Belt Thickness (mm) | Manufacturing Range | Sleeve Width (mm) | Length Designation | |

|---|---|---|---|---|---|---|---|

| Min. (mm) | Max. (mm) | ||||||

| HT-TP2-5M | 5.00 | 2.06 | 3.80 | 300 | 2250 | 460 | Lp |

| HT-TP2-8M | 8.00 | 3.48 | 6.00 | 344 | 4464 | 460 | Lp |

| HT-TP2-14M | 14.00 | 6.02 | 10.00 | 966 | 4578 | 420 | Lp |

| HT-TP2-S5M | 5.00 | 1.91 | 3.40 | 350 | 2525 | 460 | Lp |

| HT-TP2-S8M | 8.00 | 3.05 | 5.30 | 376 | 3200 | 460 | Lp |

Product Label

Contitech

Contitech A G, A division of Continental AG is the world's largest specialist for rubber and plastics technology in the non-tire rubber sector. The company is one of the first three leading players in its product category in India and enjoys strong goodwill with its clientele

We provide belts in a wide range - Timing Belts, HTD Belts, STD Belts, Variable Speed Belts, CXP Syncroforce HTD Belts, CXA Syncroforce HTD Belts, Extreme Syncroforce HTD Belts, Synchrochain Heavy Duty Belts

Carlisle

Carlisle Companies Incorporated is a global diversified company that designs, manufactures and markets a wide range of products that serve a broad range of niche markets including commercial roofing, energy, agriculture, mining, construction, aerospace and defence electronics, medical technology, foodservice, healthcare, sanitary maintenance, transportation, general industrial, protective coating, wood, specialty and auto refinishing.

Bando

Bando India is the Indian sales, marketing and manufacturing subsidiary of Bando Chemical Industries. Bando Chemical Industries, with 17 plants in 15 countries, is headquartered in Kobe, Japan and for more than 100 years has been pioneering technologies and development of all types of power transmission products.

SWR

SWR has over 65 years's experience in manufacturing of rubber V - belts and conveyors at ISO certified production facilities with latest production lines from Germany. SWR India offer the widest range of belting accessories and other related items of world class Quality for mechanical power transmission at competitive prices with assurance of Service with Reliability thereby providing unmatched value for money.